Have any questions?

Products

Lorem ipsum dolor sit amet consectetur adipiscing elit. Maecenas faucibus mollis interdum festibulum id ligula porta felis Lorem ipsum dolor sit amet

SuperHawk Motors

TomaHawk’s new SuperHawk series motors are on the cutting edge of mud motor technology, strength and performance. All major torque carrying components including the bit mandrel and transmission couplings have been redesigned and enlarged to handle the increased torque of “Even-Walled” and “Hard Rubber” power sections. Thrust and radial bearing capacity has been increased and a new, improved carbide coating used on radial bearings provides extended wear life. A uniquely designed mandrel catch device provides reduced stress concentration over previous designs and supports the mandrel shaft reducing bending stress. A redesigned stator connection reduces cracked threads and provides protection from corrosive drilling fluids.

These improvements allow the SuperHawk motor to easily handle the most extreme drilling conditions while utilizing the increased torque from “even-walled” and “hard rubber” power sections. This enables drillers to maximize rate of penetration and be highly competitive in Today’s drilling market.

SuperHawk motors are available in sizes ranging from 1 11/16” to 11 ¼” diameters and are available in several configurations including adjustable bent housing, fixed bend housing, or straight housing with TomaHawk’s jaw clutch or flexshaft driveshaft.

Optional Features

- Float Bored top subs

- Slick, integral blade, or welded blade stabilizers

- Flex shaft drive coupling for straight or bent motor applications

- Rotor catch

- Flow bypass rotor nozzle

Standard Features

- Mud Lubricated Bearing Pack

- High Strength Forged Alloy Steel Output Shaft

- Bearing Housing with screw on stabilizer

- Through hardened thrust bearing races

- BlackTip premium upper and lower radial bearings

- Super Strong jaw clutch drive couplings

- Straight, fixed bend, or adjustable bent housing

- Customer selected power section from any manufacturer

- Crossover sub (top sub)

Vestibulum nec odios suspe ndisse cursus

TALON ADJUSTABLE

BENT HOUSING

TomaHawk offers straight, fixed bend, or adjustable bent housings. The Talon series adjustable bent housings are infinitely adjustable from 0 – 3 degrees feature quick and easy angle adjustments, offer a large I.D. bore, a replaceable wear pad and non torque dependant angle alignment, which ensures there is no “slipping” or misalignment of angle settings.

(*4-degree Talon adjustable bent housings are available upon request)

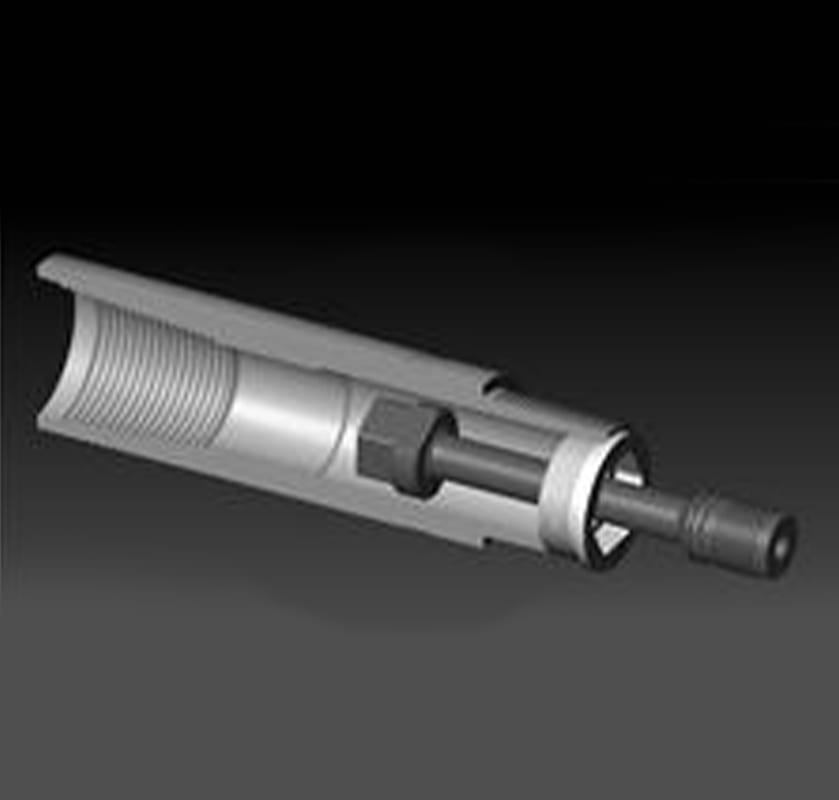

TomaHawk Transmission

TomaHawk jaw clutch flexible drive couplings feature a two-lobe design with hard metal weld on the contacting surfaces. These couplings are extremely strong, durable and can be re-worked up to three times after worn to extend the useful life.

TomaHawk’s flex-shaft is a solid flexible rod, which can be substituted in place of the jaw clutch drive couplings for straight or bent motor applications up to 2 ¼ deg. These shafts come in various configurations and materials depending on the application.

Titanium Flex Shaft

Text here….

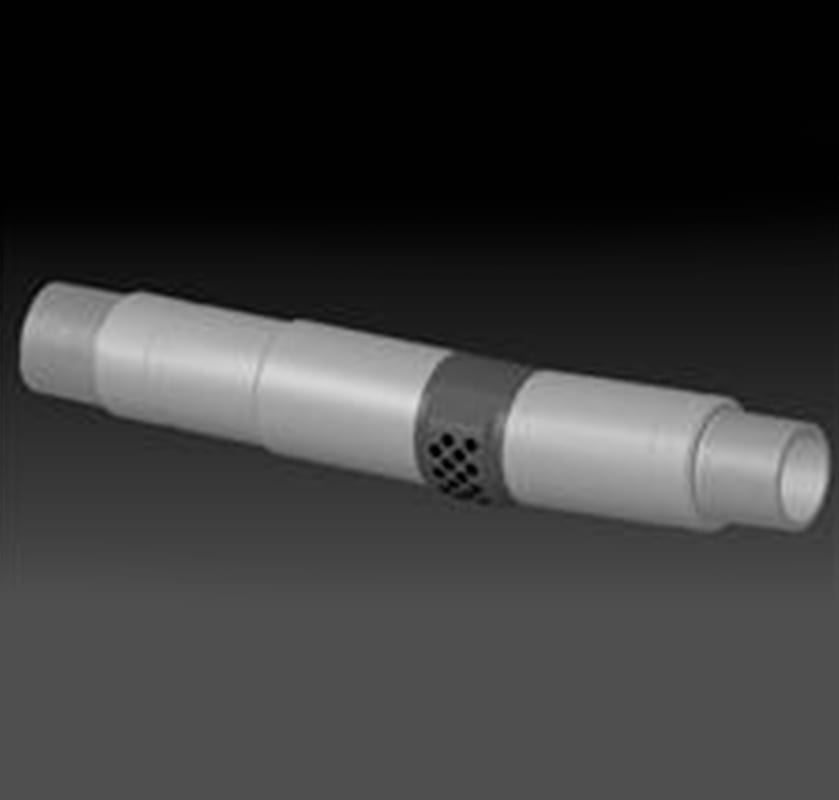

BlackTip Radial Bearings

TomaHawk now offers BlackTip radial bearings for use in its drilling motors. These bearings have proven to be extremely wear resistant, durable and cost effective. They have proven themselves in the harshest drilling environments where other bearings have failed.

The BlackTip radial bearing consists of Tungsten Carbide tiles bonded to a steel housing. The Tungsten Carbide tiles are arranged in a dense array to maximize carbide content and wear resistance. These tiles are surrounded by a high quality carbide matrix material. This formulation makes the BlackTip bearing approximately 92% Tungsten Carbide by volume providing superior wear resistance.

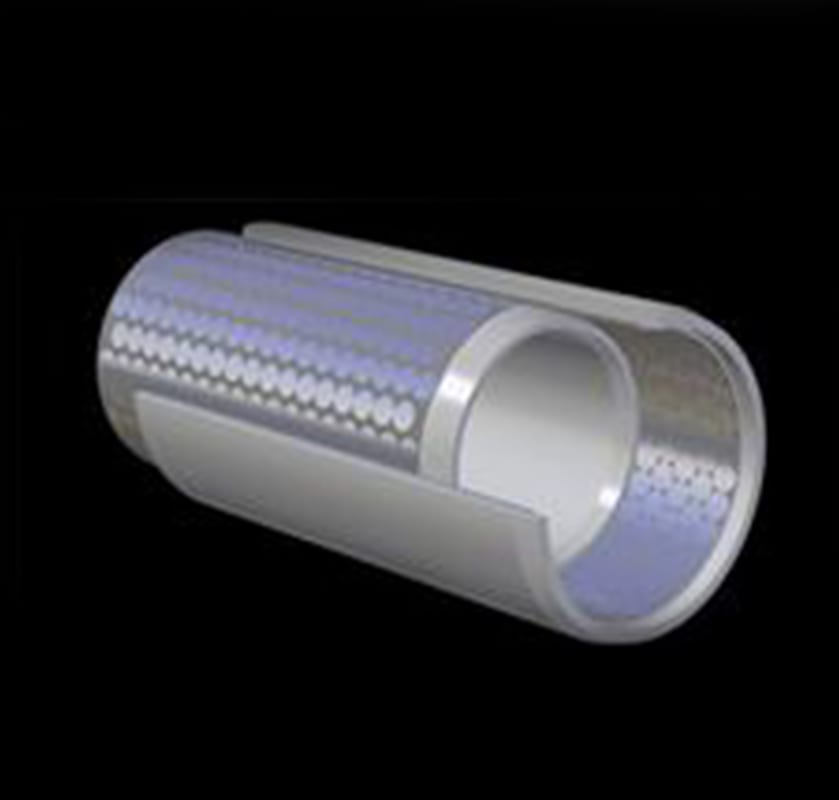

Power Sections

TomaHawk’s bearing and drive assemblies can be configured to accept virtually any manufacturers’ power section. We can accommodate any lobe/stage configuration from high speed, low torque 1/2’s up through the high torque low speed 9/10’s. We can also accommodate the new “even walled” and “hard rubber” power sections.

Top Sub

The top sub is available with a customer specified top connection. Other options include a rotor catch, which prevents loss of the rotor and possibly the entire motor in the event of an outer connection failure and an optional float bore which eliminates the need to run an additional float sub above the motor.